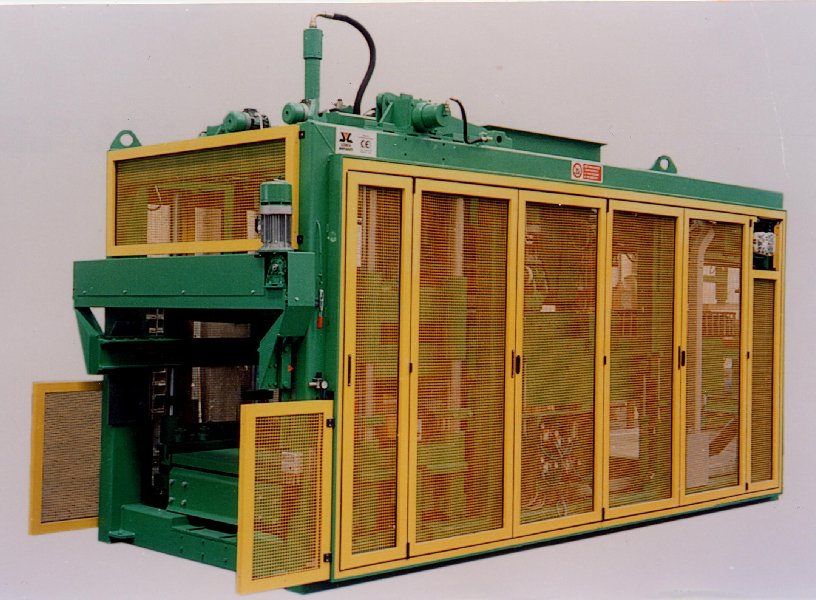

STATIONARY CONCRETE BLOCK MACHINE: LC 100

| Ideal concrete block machine for large production in complete automatic concrete block plants; | |

| Suitable in complete automatic concrete block plants or in linear plants with operator for transportation of concrete elements to the curing area; | |

| Controlled vibration composed of 4 electro-synchronized masses allowing frequency variations within the same cycle; | |

| Vibration adaptable to the various concrete mixes containing different types of aggregates: expanded clay, pumice, lapilli, etc; | |

| Automatic system to connect/disconnect and lock/unlock the mould and tamperhead; | |

| Centralized control panel equipped with SIEMENS© PLC electronics and programmed for automatic functioning of the concrete block press machine including: |

| Production parameters for all the various concrete block products stored in memory to allow rapid setup of the plant during a change in the product manufacture (tamperhead height, height of the mould, vibration force, vibration frequency, etc); | |

| Electronic archiving of all production data and statistics; | |

| Breakdown and alarms; | |

| Synoptic panel for immediate status of the concrete press plant; | |

| Programmed maintenance; | |

| Equipped to communicate using modem for LOREV diagnostic assistance and software updates. |

| Hydraulic plant with double pump, accumulator oil/nitrogen with filtration and water/air blast cooling systems | |

| Tele-Assistance system-Allowing remote connection by LOREV technicians to the individual system for effective and comprehensive technical assistance | |

| Optional: |

| Double feed system for refined mix; | |

| Device for pulling the pallets. |