| Available in 2 versions: Automatic (1010/A) and Semi-automatic (1010/CO) |

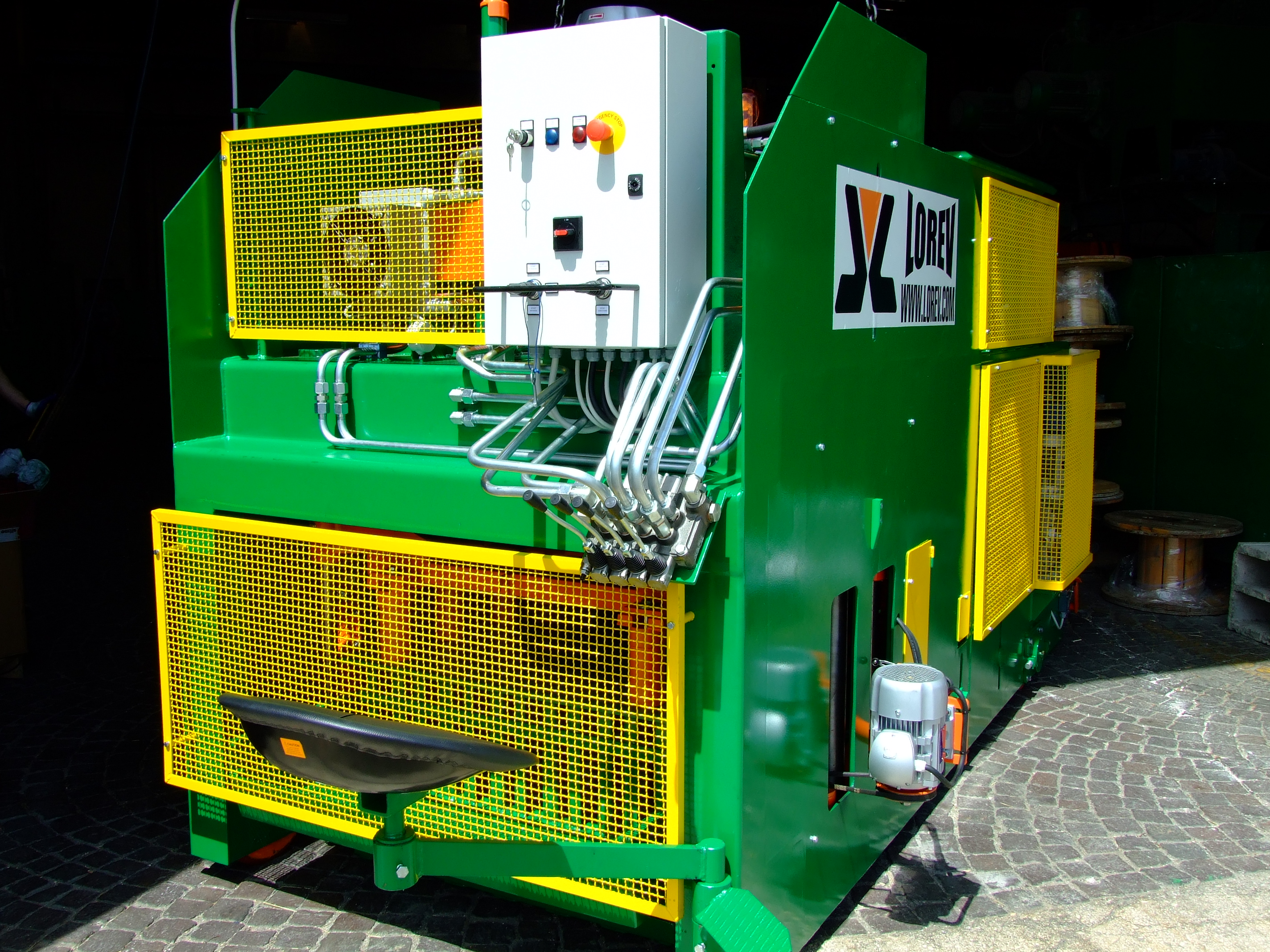

| Sturdy, simple concrete block machine requiring minimum maintenance |

| Ability to produce concrete blocks with heavy and light aggregates (expanded clay, pumice, lapilli, crushed brick) |

| Ability to produce concrete blocks with holes open, closed, half closed |

| Height of concrete elements ranging from 20 to 25 cm |

| Working surface area 104 cm x104 cm |

| Minimum distance between the stripping of 10 cm (adjustable) |

| Minimum distance between the rows of about 35 cm |

| Cycle time from 20 to 40 sec.; Average 30 seconds (1010/A) |

| Fully automatic, programmed and controlled by electronic equipment (1010/A) |

| Easy programming cycle, performed by keyboard display (1010/A) |

| Each phase of the cycle is easily adjustable using the control panel(1010/A) |

| Manual hydraulic distributor with four levers for controlling the movement of the feed drawer, tamper-head, mould and the steering wheel (1010/CO) |

| Forward/reverse movement with two speed steering wheel |

| Tele-Assistance system-Allowing remote connection by LOREV technicians to the individual system for

effective and comprehensive technical assistance |